|

|

|

| Complete structure of the triplex extruder 3,000 kg/h Mazbra Mazzoni Group |

|

Complete structure of triplex bar soap extruder.

Composed of:

- Extruder for manufacturing bar soap.

Brand | manufacturer: G.Mazzoni.

Model: Triplex.

Approximate capacity: 3,000 kg/h of bar soap.

- Internal carbon steel liquid soap feeding tank with water and steam heating jacket with several connections for soap, water and steam inlet and outlet.

Approximate capacity: 2,000 liters.

Equipped with a floating float to maintain a constant level of soap in the tank, activated by means of a micro-switch to start or stop the filtration pump.

- Complete external vacuum tower.

Manufacturer | brand: Mazzoni.

Description of MAZZONI facilities:

Composed of a variable flow filtration electric pump, equipped with a speed reducer, V-belts, pulleys, base for an electric motor, and a special belt mounted on the reducer. The entire assembly is assembled on a single cast iron base with an electric motor.

A special filter for filtering liquid soap, consisting of a carbon steel container with an external steam heating jacket, quick-closing lid with screws, hinges and butterflies.

A filtration sieve made entirely of stainless steel, and a spare filtration sieve. The assembly is equipped with several unions and connections for the inlet, outlet and discharge of soap and steam.

A buffer tank for feeding liquid soap, made of carbon steel, with a water and steam heating jacket with several connections for the inlet and outlet of soap, water and steam, with an approximate capacity of 2,000 liters. Equipped with a floating float to maintain a constant level of soap in the tank, activated by means of a micro-switch to start or stop the filtration pump.

A variable flow feed pump to continuously feed the soap from the tank to the vacuum atomization tower, including a speed variator-reducer, coupling sleeve between the variator reducer and the pump, pulleys and “V” belts. All parts made of special, tempered steel.

Vacuum system consisting of a barometric column and boosters for the dryer.

Two gear pumps for soap with a capacity of 5,000 kg/h with a motor variator.

One gear pump with a capacity of 30,000 kg/h.

A dryer with a vacuum chamber, three extruders and two branches for the exit of the soap bar for cutting with a capacity of 3,000 kg/h.

A centrifugal pump for bleach, with a capacity of 10,000 kg/h.

A stainless steel tube-type temperature regulator with soap outlet and inlet cones made of the same material, and the external tube for the circulation of the heating steam made of thick carbon steel, complete with unions and fittings. All flanges are supplied with the corresponding counterflanges.

A vacuum atomization apparatus made of carbon steel, external jacket, reduction group controlling the central shaft and the scraper devices located inside the hermetrically sealed chamber with oil bath lubrication.

Central shaft supported by original SKF ball bearings, with steel scrapers and adjustment devices. With lighting and inspection windows.

Two preliminary drawing machines for working under vacuum to be paired with the atomization chamber frame made of thick steel plate and electrically welded.

Gears made of forged steel operating in an oil bath, all shafts on original SKF high-capacity bearings.

Carbon steel extrusion screw housing cylinders with a jacket for cooling water circulation, the interior of which is fitted with helical guides to direct the water in order to increase cooling by equidistribution.

Device for the first refining of soap with a sieve housing, interchangeable for dry filtration, with a multiple knife for cutting the small cylinders of soap at the outlet.

Mechanical clutch to make the machine independent of the electric motor, with electric motor.

A vacuum connection chamber between the two drawing machines, fitted with a jacket for cooling or heating water circulation, complete with lighting and inspection windows. Another drawing machine, this time with a conical head and thermostatic control for heating the extruded bar of soap.

An automatic steam pressure reducer.

A high-capacity steam jet thermocompressor to increase the vacuum in the atomisation apparatus.

Frigo-barometric group to lower the temperature of the cooling water circulating in the drawing mills, with barometric condenser, auxiliary thermo compressor, frigo-barometric evaporator, centrifugal pump with electric motor and base, bottom container for constant level, thermometers and pressure gauges.

A large-capacity steam jet thermocompressor to increase the vacuum in the atomization apparatus.

A refrigeration-barometric unit to lower the temperature of the cooling water circulating in the drawing machines, with a barometric condenser, auxiliary thermocompressor, refrigeration-barometric evaporator, centrifugal pump with electric motor and base, a constant-level bottom container, thermometers and pressure gauges.

A silicate injection unit including a dosing pump, a small stainless steel tank for feeding the solutions, a steel feeding circuit with a safety valve, a pressure regulating valve, a check valve, etc.

An automatic cutter used to automatically cut the continuous bar of soap at the drawing machine outlet into bars or tablets of the desired size and weight, formed by a special chain, it is entirely made of steel and cast iron and all the moving parts are mounted on bearings and mounted on a steel frame.

Adapted to the cutter is a bronze cylinder with a steel shaft, mounted on SKF bearings to allow the engraving of bars of different thicknesses.

Two conveyor belts for the bars of soap.

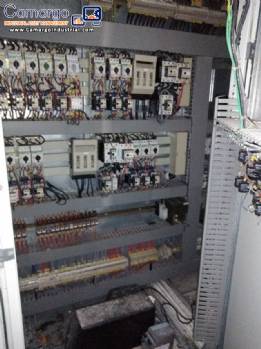

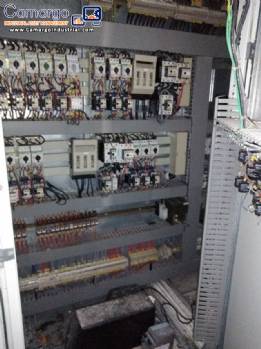

A general “pulpit” type panel, comprising the remote switches of the various electric motors installed. |

Brand:

G.Mazzoni, Mazbra Mazzoni

|

|

|

|

|

|

Main suggestions:

|

|

|

Brand: G.Mazzoni, H. Bremer, Mazbra Mazzoni, Mazzoni

Complete industrial line for manufacturing bar soap.

Composed of:

- Extruder for manufacturing bar soap.

Brand | manufacturer: G.Mazzoni.

Model: Triplex.

Approximate capacity: 3,000 kg/h of bar soap.

- Complete external vacuum tower... |

|

|

|

Brand: Dal Mak

Complete sealing line for rolls and/or prismatic pieces with length up to 2.5 meters, bundling process.

Brand: Dalmak, Dal Mak.

Type U Sealer, manufacturer Dalmak.

Complete retrofitted equipment.

It packs reels of fabrics, carpets, synthe... |

|

|

|

Brand: ARV, Bosch, Fabrima, Moinhos Tigre, Semco, TekPack, Tigre

Components: Coel, Dakol, Danfoss, Festo, Fotek, GWA, JHM, Parker, Siemens, Switron, Unitronics, WEG

Complete line for the manufacture of chocolate powder and other blenders.

With high automation and space optimization, compact machines with structures for verticalization (platforms, mezzanine, elevator, connections, conveyor threads, dimensioned... |

|

|

|

Brand: Braesi

Complete plant line for fruit pulp production.

Plant composed of the following equipment:

2 Braesi pulping machines working in two stages (more efficient process).

Semi-automatic filling machine.

Automatic filling machine.

2 industrial... |

|

|

|

Brand: Masipack

Automatic Vertical Multihead Packaging Machine.

Complete multihead packaging system with conveyor belt, platform, and vibratory silo to feed the multiheads.

Manufacturer | Brand: Masipack.

Composed of:

- Automatic vertical 2-lane packagin... |

|

|

|

Complete kitchen for malt production.

Composed of:

- 2-roller carbon steel malt mill.

Features:

• Approximate capacity: 700 kg/hour.

• With a 3 HP motor.

• Epoxy-painted metal structure for fixing the mill and with a bag holder for ... |

|

|

|

Brand: LIBRASIS

Stainless steel horizontal internal paddle mixer.

Manufacturer | Brand: LIBRASIS.

Approximate capacity: 300 to 1,000 liters.

For products such as premixes, feed, and dietary supplements (animal and human).

Year of manufacture: 2024.

Ne... |

|

|

|

Brand: Dedini

Silos complete with structure / system for receiving, storing and transporting flour.

Year: 2003.

They were used in the food industry for the production of biscuits.

6 flour silos of 25 tons each.

5 silos of 165 m³ each.

1 sugar silo o... |

|

|

|

Brand: Dal Mak

Complete line for packaging window frames, metal profiles and carpets.

Brand: Dal Mak.

Composed by:

Product entrance mat.

Sealer for thermo shrinkable film, with side sealing (U-sealing), special for saving films (when the L-sealing is pu... |

|

|

|

Brand: Nelpas

Linear filling machine with 6 pistons filling system.

Manufacturer: Nelpas.

Year: 2012.

The equipment is undergoing a major overhaul, with all mechanical, pneumatic and electrical parts being completely disassembled and checked.

The equip... |

|

|

|

Brand: Milainox

Complete industry company for the manufacture of guarana and teas in cups.

The industry is structured to manufacture two flavors of guarana and three flavors of mate tea.

Approximate productivity: 1000 boxes / day.

Boxes with 24 units.

Fact... |

|

|

|

Brand: Ata, Braibanti, Pavan Group

Line composed by:

trademark boiler Ata, with production of 650 kg/h steam with heating surface to 20 m ³, 120 psig working pressure, test pressure 240 psig. GMP equipment fuel with electric control board.

Pneumatic flour with a capacity of 20... |

|

|

|

Brand: Incalfer

Line continues to produce chips Incalfer.

Capacity: 300 Kg/h (finished product).

Composed by:

-primary screw-Feeder Used reviewed.

Receiving silo potatoes totally built in stainless steel 304.

Screw conveyor (helical) built in stainless s... |

|

|

|

Brand: Italvacuum

Vacuum oven with carbon steel structure and stainless steel internally.

Manufacturer: Italvacuum (Italy).

It has a cooling, heating and vacuum system (complete).

For the food industry, pharmaceuticals, animal health, cosmetics and beauty pro... |

|

|

|

Brand: Ecirtec

Components: SEW

Continuous press for extracting vegetable oils.

System for extracting vegetable oils with continuous press and filter press.

It was used to extract cocoa butter.

- Continuous Press.

Manufacturer: Ecirtec.

Model: MPE-100 S PI.

Equipm... |

|

|

|

Brand: PRB

Grouping blender.

Mark PRB.

Model FAR XE.

Production up to 70 u / m.

Standard Voltage: 400 V. 3 Phase 50 Hz + G (earth) + N (neutral).

Control Voltage: 24 VDC.

electronic platform Elau Schneider.

Compressed air at 6 bar.

Noise... |

|

|

|

Brand: Brasforno, Cozil, Haas, Icaterm, Klainox, Tecnomecal

Components: Bitzer, Brahma, Danfoss, Dungs, Hofomat, Siemens

Line for making empanadas.

Brand Name: Tecnomecal.

Composed by:

Forming of empanadas.

Brand Name: Tecnomecal.

Model: ML-300.

Lamination of two seasons.

Brand Name: Tecnomecal.

Model: 600.

Two cylinders of imported mass Argenti... |

|

|

|

Brand: Erli

Encapsuladeira semi-auto with powder feeder, vacuum pump, electronic speed control for powder weight control inside the capsules, funnels and powder capsules supply, stainless, and carbon steel structure painted, feet, and lock table in stainless ste... |

|

|

|

Brand: Palley

Industrial oven.

Model: Palley and-245.

Internal dimensions: 1,800 m x m x 1,740 2,560 m.

all Structure in steel SAE-1020, with rock wool thermal insulation on all sides.

Standard axial ventilation, temperature up to 100° c.

Heating through... |

|

|

|

Brand: Anacom, Drill Machine, Franho, Galax, Index, Invicta, Morand, Morganite, Nardini, Rocco, ROMI, Tecnoavance

Components: Fagor, Fanuc, Siemens

Metallurgical industry for the manufacture of wheels (vehicle hoops).

Date of foundation: 1987.

The company has as an activity the manufacture of sports wheels for motorcycles and mopeds, being alloy wheels and hubs for wheels.

The company i... |

Others suggested equipment for you:

|

|

|

Brand: IMSB, Rodopac

Automatic Capper with 6 nozzles.

Manufacturer: IMSB.

Model: TSB 25.06

6 Nozzles.

Measures 40 mm: 1.50 mm x 1.20 mm x 2.30 mm height.

Bondone and thread plastic bottles of 850 ml.

Capacity of 150 bottles per minute.

Weight 1,100 kg.

... |

|

|

|

Brand: Rodrinox

- Handling reactor.

- Brand: Rodrinox.

- Pressure equipment used for the manufacture of cream, ointment

And similar products.

- It has motor with reducer.

- Spindle shaft.

- Great construction.

- 316 stainless steel.

- Capacity ... |

|

|

|

Stainless steel tank with internal cooling like tina.

220 litres capacity.... |

|

|

|

Brand: Incal

1 Pot for making chikki and other candy.

Brand: Incal.... |

|

|

|

Brand: Alfa Laval

- Transfer pump in stainless steel.

Type Sol 10c2.

- B 190 mm.

- Brand: Alfa Laval.

... |

|

|

|

Brand: Biasinox

- Tank with a maximum capacity of 1000 liters.

- Brand: Biasinox.

- Dimensions:

- 2.00 m high.

- 1,10 m in diameter

- 0.70 m stand (feet).

- Material stainless steel 316

- With tapered bottom.

- Output of the lower part.... |

|

|

|

Brand: Hebleimar

Extruder for cereal dough, sweets and consistent product.

- Brand: Hebleimar;

- Model: HEX - 400.

- Material: Stainless steel.

- Voltage: 220 V Three-phase.

- Components: 1 engine of 3.7 KW of power.

- General characteristics: It ha... |

|

|

|

Brand: Claumaq

Mixer.

Brand: Claumaq.

Stainless steel internal tank, shaft and spatula

Capacity: 100 kg.

Measures: 1.80 m x 1.00 m x 1.54 m.

... |

|

|

|

Brand: Alsop

Stainless steel tank with simple jacket without mixer.

Brand: Alsop.

Capacity 200 liters.

Approximate measurements:

Tank height: 74.5 cm.

Height feet: 96.5 cm.

Diameter: 62 cm.... |

|

|

|

Brand: Jormary

Container with 1 container nozzle.

Brand: Jormary.

Model: ES1 Plus.

Stainless steel equipment, polished, including inside the lung funnel, facilitating hygiene.... |

|

|

|

Stainless steel tank.

1000 litre capacity.

With motor and reducer.... |

|

|

|

Stainless steel storage tank.

500 liters capacity.

With carbon steel support.

Output of the product from the side.

With motor and propeller shaft.... |

|

|

|

Coated tank for melting of chocolate in stainless steel.

- It has 3 motors with power: 0,5 Kw, 1,5 Kw, 0,75 Kw.

- Equipment has temperature adjustment, transfer pump and mixer for

Homogenization.

- Capacity: 400 / 500 liters.... |

|

|

|

Brand: Inoxil

- Pressure reactor in stainless steel 316 L with agitator and homogenizer.

- Literature capacity: 140 liters.

- Brand: Inoxil.

- Pressure equipment used for the manufacture of cream, ointment

And similar products.

- It has two engines... |

|

|

|

Stainless steel tank with 1,500 liters with motor and reducer.

- Tank size 1,20 x 1,20 x 3,14 x 1,40: 4 = 1582 liters = 1500 liters.

- Engine of 5vc 1725 rpm.

- Motor of 220 v / 380v / 440 v.... |

|

|

|

Brand: Niva Pack

Components: Allen-Bradley

Vertical powder packer with volumetric system

Brand Name: Niva Pack.

Model: Absolut 350.

With pneumatic system of dosage of trough.

Machine with shape and thread.

Electric panel.

Allen Bradley PanelView 300 Micro Vision Panel.

Al... |

|

|

|

Storage tank.

Capacity: 2,300 liters.

Storage tank stainless steel.... |

|

|

|

Brand: G.Mazzoni, Mazzoni, Mazzoni LB

Refining mill with 3 cylinders, 600 mm wide.

Brand: G.Mazzoni.

With equipment control panel.

Approximate dimensions:

Length: 720 mm Useful: 600 mm.

Diameter: 250 mm.

Engine: 20 HP.... |

|

|

|

Brand: ACG, Almapal, Pam Pac

- Blistadeira.

- Brand: Pam Pac.

- Model: Cartoblis.

- Machine for manufacturing blister packs / medicine trays.

- It has tool set for different sizes and formats.

- Excellent condition.

- Machine formatted to work with alu + PVC.... |

|

|

|

Stainless steel tank with simple shirt with lid without agitator.

Capacity: 1,000 liters.

Measures:

diameter: 1000 mm.

height: 1300 mm.

overall height: 1900 mm.... |

|

|

|

Brand: Tirelli

Linear filling with 4 nozzles.

Brand: Tirelli.

Model: GVJA.

Machine to work on speed.

Imported equipment, great condition, has little time before their date of manufacture.

Sell the Tirelli labeller who was from the line (fillin... |

|

|

|

Brand: Serpack

Components: Atos, WEG

Vertical powder wrapping machine

Brand Name: Serpack.

Model: SPK 250.

Machine with panel.

Inverter Weg CFW 8 and Weg CFW 10.

Servo driver / Servo converter / Servo converter Weg SCA 04.

With servo motor, internal thread of dosage an... |

|

|

|

Brand: G.Mazzoni, Mazzoni, Mazzoni LB

Homogenizer for soaps with 3 cylinders.

With fine pressure adjustment.... |

|

|

|

Tank insulated with refrigeration, internal in stainless steel and external in carbon steel.

Capacity of 1,300 liters.... |

|

|

|

Dryer Spray Dryer in stainless steel.

Drying capacity between 100 and 150 kg hour.

It has nozzle because it is high pressure.

It was used in the food industry.

Drying capacity between 100 and 150 kg hour.

Unbranded equipment was assemb... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Camargo Industrial acts exclusively as an advertising platform. All information, photos, descriptions, conditions, and equipment compliance are the sole responsibility of the advertisers, and it is up to the buyers to verify their accuracy before purchasing. Camargo Industrial does not guarantee the accuracy, completeness, legal and technical availability of the advertised equipment.

Workplace safety with machinery: The platform does not perform inspections or certifications. The suitability of equipment to standards is the responsibility of sellers and buyers.

|

|

| |

|