|

|

|

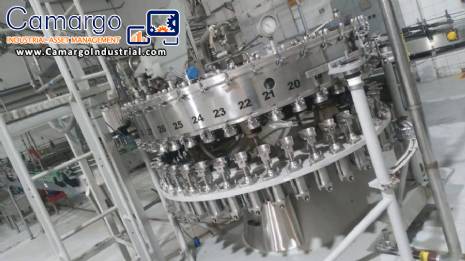

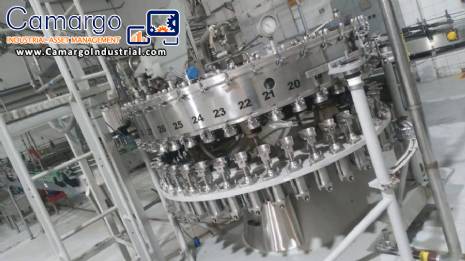

| Line for brine filling manual product insertion and automatic capping |

|

Line for brine filling, manual product insertion and automatic capping.

Composed by:

Glass bottle capper.

Model: US 60.

Application: automatic closing of glass jars (300g palm heart) with screwable metal lids.

Manufacturing material: AISI-304 stainless steel.

Layout code: A03.

Rated capacity: 60 packages per minute.

Approximate dimensions of the main unit (W x W x H): 500 x 2000 x 1700 mm.

Fully automatic continuous linear closing system.

Automatic lid releaser and positioner.

Pre-threading and cap preparation system.

Threader head with adjustment for pots height from 80 mm to 180 mm and 0 of lids ranging from 58 mm to 74 mm.

Steam supply system including injectors; modulating valve; trap; and condensate catcher.

Closing head actuation via SEW gearmotor.

Feeding and output conveyor for stainless steel platform pots; Conveyor drive via SEW gearmotor.

Height adjustment system via SEW gearmotor.

Feet with adjustable support shoes.

Automatic cap feeder.

Rated feeder capacity of 60 units per minute.

Reservoir for 1 box of lids (1500 units).

Feet with adjustable support shoes.

Magnetic elevator with magnetic pressure regulation.

Special non-stick conveyor belt.

Cap missing detection sensor.

Cap overflow detection sensor.

Mechanical cap picker.

Lid spout with adjustment for 58mm and 63mm and 74mm lids.

Cap return spout.

SEW gearmotor;

General finish G320.

Quantity: 01 unit.

DOUBLE TANK FOR BRINE PREPARATION AND ACCUMULATION 1000 LITERS EACH.

Driven by integrated pumps and mixers.

STAINLESS STAINLESS POT ENTRANCE CONVEYOR BELT.

With side guides in stainless steel with integrated motor.

BRINE FILLER DOSER IN CASCADE AND OVERFLOW.

In stainless steel, stainless steel snake model belt, driven by a gearmotor, cascade dosing by overflow; with centrifugal pump and brine reprocessing with preheating container, flow adjustment valves, controlled steam heating coil by WEG PLC villa.

THREADER AND COVER OF LINEAR STAINLESS POTS IN STAINLESS STEEL.

Feed preheated by steam capacity 40 pots per minute with height adjustment from 80 mm to 180 mm, lids ranging from 58 mm to 74 mm, automatic lid feeder with reservoir for 1 box of lids 1500 un with magnetic lift. |

|

|

|

|

|

|

|

Main suggestions:

|

|

|

Machine for candy to put in the bag

Mixer with two axles

complete line of Dairy

Tube

Packinghouse to 15 Kg

3-wire machine mechanical Stretcher screens with a maximum capacity of 40 cm, 4 x 4 Carousel machine

machine to make baby socks, ... |

|

|

|

Brand: Alfa, Amandus Kahl, Tigre

Bran pelleting line with mill and drying oven.

Pellet mill for bran pelleting.

Manufacturer: Kahl Amandus Kahl.

Model: 33-390.

With new spare parts.

Stainless steel hammer mill.

Manufacturer: Tigre.

Model: ASN 6.

With 6hp moto... |

|

|

|

Brand: Biasinox, Fortress, MVL

Line for manufacturing soft chocolate sprinkles.

Approximate production capacity: 24 tons per month.*

*considering 8 hours of work per day.

Line composed of:

- Stainless steel jacketed pan with internal steam system.

With carbon steel st... |

|

|

|

Beer bottling line, consisting of depalletizing, conveying, rinsing, filling, can seamer and level inspection.

Depalletizing machine for cans per hour.

In-line conveyor.

Mezzanine walkway.

Rotary filling machine for carbonated beer.

Wi... |

|

|

|

Brand: Brapenta, Masipack, Metalgraf, Neife, SLP Indústria de Máquinas

Components: Siemens, WEG

Can filling system.

Line for filling powdered products in cans, jars and bottles.

The line worked with 400 g cans and a taller 510 g can.

Depending on the density of the product, it can fill up to 600 grams.

- Dosing filling machine for j... |

|

|

|

Brand: Piróg

Line for the production of Nhá Benta Dan Top.

Brand: Piróg.

With blower to remove excess product.

Dimensions of the cover: 2.20 m high x 160 m wide x 1.45 m long

Mat dimensions: 895 mm width.

With motors, water pump and electrical pane... |

|

|

|

Brand: Allpacking, Bralyx, Braslaer

Line for the manufacture of sweets and snacks.

Brand: Braslaer.

Automatic packing machine.

Flow pack system.

CLP: Schneider.

Turntable tray.

Brand: Bralyx.

Stainless steel.... |

|

|

|

Brand: BBULL TECHNOLOGY, Zegla

Complete filling line for cans of juices and still drinks.

For Hot Fill cans with nitrogen application.

Manufacturer | brand: Zegla.

Year: 2010 / 2011.

Approximate filling capacity: up to 6000 cans / hour.

Line composed of:

- Depall... |

|

|

|

Brand: Maqmundi

Packaging line for nuts in jars.

Composed of:

- Stainless steel storage table for jars.

Model: LPE - RAT120.

Year: 2018.

- Multi-head dosing scale.

- Input conveyor for feeding the jars.

Model: LPE - PFM01.

Voltage: 220 V.

... |

|

|

|

Packaging, counting and capping line for capsules and other products.

Composed of:

Stainless steel feeding table.

Automatic capsule counter with PLC.

Model: CC 120 - K.

Automatic capping machine with automatic cap feeding.

Automatic... |

|

|

|

Brand: Masiero

Line for mechanical extraction of vegetable oils, including oilseeds such as peanuts, sunflowers, castor beans, among others.

Line installed in 1985 but never operated.

Composed by:

Expeller extractor press.

Manufacturer: Masiero.

type... |

|

|

|

Brand: Jaf Inox

Complete line for the production of bean to bar chocolate.

Brand: JAF Inox.

Approximate capacity: 10 kilos.

Composed by:

Peeler 5 decks with silo.

Cocoa seed roaster.

Homogenizing shell.

5 roller refiner.

Transfer pump.

Com... |

|

|

|

Complete line for the manufacture of steel sponges and steel wool.... |

|

|

|

Brand: ARV, Bosch, Fabrima, Moinhos Tigre, Semco, TekPack, Tigre

Components: Coel, Dakol, Danfoss, Festo, Fotek, GWA, JHM, Parker, Siemens, Switron, Unitronics, WEG

Complete line for the manufacture of chocolate powder and other blenders.

With high automation and space optimization, compact machines with structures for verticalization (platforms, mezzanine, elevator, connections, conveyor threads, dimensioned... |

|

|

|

Brand: R.Camargo

Line for production of ice cream of pasta.

Composed by:

Producer of horizontal ice cream.

Brand: R.Camargo.

Model: PHD 80/100.

Capacity: 80 L / 100 L / h.

Tub of autonomous maturation.

Brand: R.Camargo.

Capacity: 180 L.

Hom... |

|

|

|

Set for making soft mocha and toffe.

Composed of rotating vertical rod wires and cutting.... |

|

|

|

Brand: Hansella

Cream rinsers with piston.

Brand: Hansella.

Model: Werke.... |

|

|

|

Brand: Thermoforming

Bottling line for trademark Termoforming pots (Italy), for packing food type creams "io io cream", with thermoforming system, aluminium seal with pneumatic filling system for the line... |

|

|

|

Brand: Hebleimar, Piróg

Line for the production of sweets like "denies tit", Dan Nhá.

consisting of:

2 drip trays of marsmallow with 14 burners each.

cooling tunnel and chocolate brand cobrideira Piróg.

Measures: width 1.10 m by 10 m length and height 1.25 m.

widt... |

|

|

|

Brand: Rotia

Line for the manufacture of cereal bars brand new semi Rotia with approximately 15 m in length.

consisting of the following equipment:

-

-Laminator cutter.

-

cooling tunnel-Cozinhadores

-Buller.

-k12k * filling * system-water heating syst... |

|

|

|

Brand: Inbramaq, Masipack

Line for production of up to 250 pounds of finished product, composed of:

rotary cutter/Rotary screw/Alimentador Washer/Trocador/Silo with heat metering/screw Feeder trough/Fritador Keep/14 Package Masipack Scales (optional)

... |

|

|

|

Ice cream industry with a capacity of 12,000 l composed of:

- Heating tubs

- Heat exchangers

- Homogenizing pumps

- Pumps for sanitary transfer

... |

|

|

|

Cutting line for sweets and cereal bars.

Composed of:

Cylinders

Automatic cutter.

Extruder / laminator.

Horizontal rotary knives.

Transverse rotary knives.... |

|

|

|

Brand: Braesi

Complete plant line for fruit pulp production.

Plant composed of the following equipment:

2 Braesi pulping machines working in two stages (more efficient process).

Semi-automatic filling machine.

Automatic filling machine.

2 industrial... |

|

|

|

Brand: Ariete

Complete line for molded laminated biscuits, 800 kg/hour, Ariete.

Approximate capacity: up to 800 kg/hour.

Composed of:

- Two carts.

- Product cooling.

- Packaging table.

- Wire dosing and cutting machine/rose maker and molding mach... |

Others suggested equipment for you:

|

|

|

Brand: Serac

- Gravity packer for liquids.

- Machine has 1 spout.

- Machine entirely built in stainless steel.

- Brand Serac.

- Semiautomatic with dosage by electronic scale of 1 to 25 liters.

- Production of 15 / minute for packs of 1 liter.... |

|

|

|

Brand: Nocelli

- Lineariser with 6 nozzles.

- Machine built in stainless steel.

- Structure in good condition.

- Brand: Nocelli.... |

|

|

|

Brand: Promáquina

Components: CompAir, Danfoss, Nivetec, NTG, Starnox, WEG

- Complete packaging for pharmaceutical industry.

- Machine built in stainless steel.

- To pack medicine with droppers and cap.

- Complete system for:

- Feed the liquid, with lung tank and agitator to avoid decantation.

- Pump for the ... |

|

|

|

Brand: Polienva Movitron

- Pneumatic dosing machine.

- Stainless steel.

- Brand: Polienva Movitron.... |

|

|

|

Brand: Amard

- Lineariser with 6 nozzles.

- Machine built in stainless steel.

- Structure in good condition.

- Brand: Amard.... |

|

|

|

The machine is part of a line for production of SOAP g. Mazzoni.

Mat set:

1.80 m mat press input.

2.00 m mat press output.

8.00 m mat cutter output.

7.50 m mat return refining extruder.

Note: Uses for transportation of product... |

|

|

|

Brand: Boato Pack

Boato Pack Tornado 8.

Italian Machine.

Sachet filling machine for powder, like sugar, SPLENDA and similar products.

Continuous system with screw feeder, complete machine in stainless steel.

Brand: Rumor Pack

Model: Tornado 8.

... |

|

|

|

Coated tank for melting of chocolate in stainless steel.

- It has 3 motors with power: 0,5 Kw, 1,5 Kw, 0,75 Kw.

- Equipment has temperature adjustment, transfer pump and mixer for

Homogenization.

- Capacity: 400 / 500 liters.... |

|

|

|

Brand: Tirelli

Labelling machine for bottles, Cologne and perfumes.

Brand: Tirelli.

Model: Delta.

Year: 1999.

Height: 2.00 m.

Width: 1.80 meters.

Length: 2.40 metres.

Weight: approx. 300 kg.... |

|

|

|

Brand: Glória

Soda machine.

The equipment in question is used, as is.

Brand of equipment: Glory

production Details:

production: 200 packs per hour.

Number of employees: from 06 to 08 people.

Infrastructure: mt 10 x 20 Mt.

equipment details:

1 Fi... |

|

|

|

Brand: Imaaj

Used to melt Imaaj brand. (Jamapará automation and machinery industry)

Dosing machine for pastes.

DSV Model.

Filling machine can fill gel alcohol

... |

|

|

|

Brand: Omega Ice

Pump to incorporate fruit, pulp, or other products into ice cream or processes.

Product dosing pump.

Brand: Omega Ice.

Model: Mix Pump.

With lung tank.

Frequency inverter for mixing in the tank and frequency inverter in the pump.... |

|

|

|

Brand: Battenfeld Pugliese

Components: Cestari

Battenfeld Blower Pugliese.

Function: production of bottles.

Used for: manufacture of detergent bottles.

Model: BPS-2.

Year of manufacture: 1996.

Capacity: 1,000 bottles per hour.

Voltage: 220 Vac/60 hz/135.

With 3 cavities moul... |

|

|

|

Brand: Nocelli, Serac

Gravity packer for liquids.

- Machine has 1 spout.

- Machine entirely built in stainless steel.

- Brand Serac.... |

|

|

|

Brand: IMSB, Rodopac

Automatic Capper with 6 nozzles.

Manufacturer: IMSB.

Model: TSB 25.06

6 Nozzles.

Measures 40 mm: 1.50 mm x 1.20 mm x 2.30 mm height.

Bondone and thread plastic bottles of 850 ml.

Capacity of 150 bottles per minute.

Weight 1,100 kg.

... |

|

|

|

Brand: Mesal

Filling machine 10 nozzles for wax grease high viscosity.

Brand: Mesal.

Model: MEC 500/10.

Year: 2002.

Worked with domestic wax packaging.

With 10 nozzles, individual cylinder per nozzle.

With electric panel.

Production: 5,000 bo... |

|

|

|

Brand: Km Máquinas

Semi-automatic, benchtop, electro-pneumatic stainless steel capping machine.

Manufacturer | Brand: Km Máquinas.

Model: BA002.

Semi-automatic equipment, allows pressure adjustment, has a parts counter, and a height-adjustable column.

Power... |

|

|

|

Brand: Nocelli, Serac

- Lineariser with 6 nozzles.

- Machine built in stainless steel.

- Structure in good condition.... |

|

|

|

Brand: IMSB, Rodopac

Tampador automatic.

Model-TSB 25.6.

Manufacturer-IMSB.

Equipment designed for use in process lines where there is a need for automation in the closing of the plastic bottles, glass or metal. Developed to close bottles with various models of c... |

|

|

|

Brand: Tecmaes

Labeling labeling machine for flexible packaging.

Brand: Tecmaes.

For 10 mm to 115 mm labels.

Production: 30 meters per minute.

Application accuracy: Variation of 1 mm more or less.

Apply label and counter to boxes and flat products.... |

|

|

|

Brand: Zolimaq

Linear automatic filling machine.

Brand: Zolimaq.

Built in stainless steel.

With 6 dosing nozzles.

Accompanies another set of 6 nozzles for smaller products.

Filling machine with stainless steel centrifugal pump to pressurize the produ... |

|

|

|

Brand: Milainox

Filler dosing liquids in glasses, flasks and pots and semi pasty.

Brand: Milanox.

Model: M22.

Year: 2010

Approximate capacity: 2,000 cups per hour.... |

|

|

|

Brand: Serpack

Components: Festo

Filling continues Stand Up Pouch stainless.

Brand Name: Serpack.

Model: SPK 200.

For filling: Olives, meatballs and other.

Presentation of the package: Sache Stand Up Pouch.

Yield: 35 ppm.

Supply voltage: 220 V-60 Hz 3 F

pneumatic syste... |

|

|

|

Brand: Meca

Saches sealer

electronic welding machine (radio frequency)-semi automatic box

Manufacturer: Mecca.

Saddle sachets in PVC for honey, sweet milk, olive oil and what most imagine.

1-equipment application.

electronic welding machines sachet, ... |

|

|

|

Brand: Emblamaq

Flow Pack Wrapping Machine.

- Brand: Mult Pack 150.

- Voltage: 220V.

- With two engines with 1.5 kw each.

- Temperature adjustment on the jaws and lower release.

- Adjustment of the size of the packaging via format.

- Approximate sp... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Camargo Industrial acts exclusively as an advertising platform. All information, photos, descriptions, conditions, and equipment compliance are the sole responsibility of the advertisers, and it is up to the buyers to verify their accuracy before purchasing. Camargo Industrial does not guarantee the accuracy, completeness, legal and technical availability of the advertised equipment.

Workplace safety with machinery: The platform does not perform inspections or certifications. The suitability of equipment to standards is the responsibility of sellers and buyers.

|

|

| |

|